High-Pressure Laminate(HPL) and Low-Pressure Laminate(LPL/LPM)

High-Pressure Laminate(HPL) and Low-Pressure Laminate(LPL/LPM)

What is High Pressure Laminate (HPL) and Low-Pressure Laminate(LPL/LPM)?

High-Pressure Laminate (HPL) is made by pressing multi-layer resin-impregnated paper at 150℃ and 1000psi. Dense and wear-resistant, it’s for high-durability uses like countertops and medical cabinets.

Low-Pressure Laminate (LPL), or melamine board, bonds single-layer decorative paper to particleboard/MDF at 300–500psi. Cost-effective and colorful, it suits regular furniture and interior finishes.

Surface Materials Comparison: HPL VS LPL/LPM

High-Pressure Laminate

Alternative Names: Laminate, Fire-rated Board, Refractory Board

Process Overview

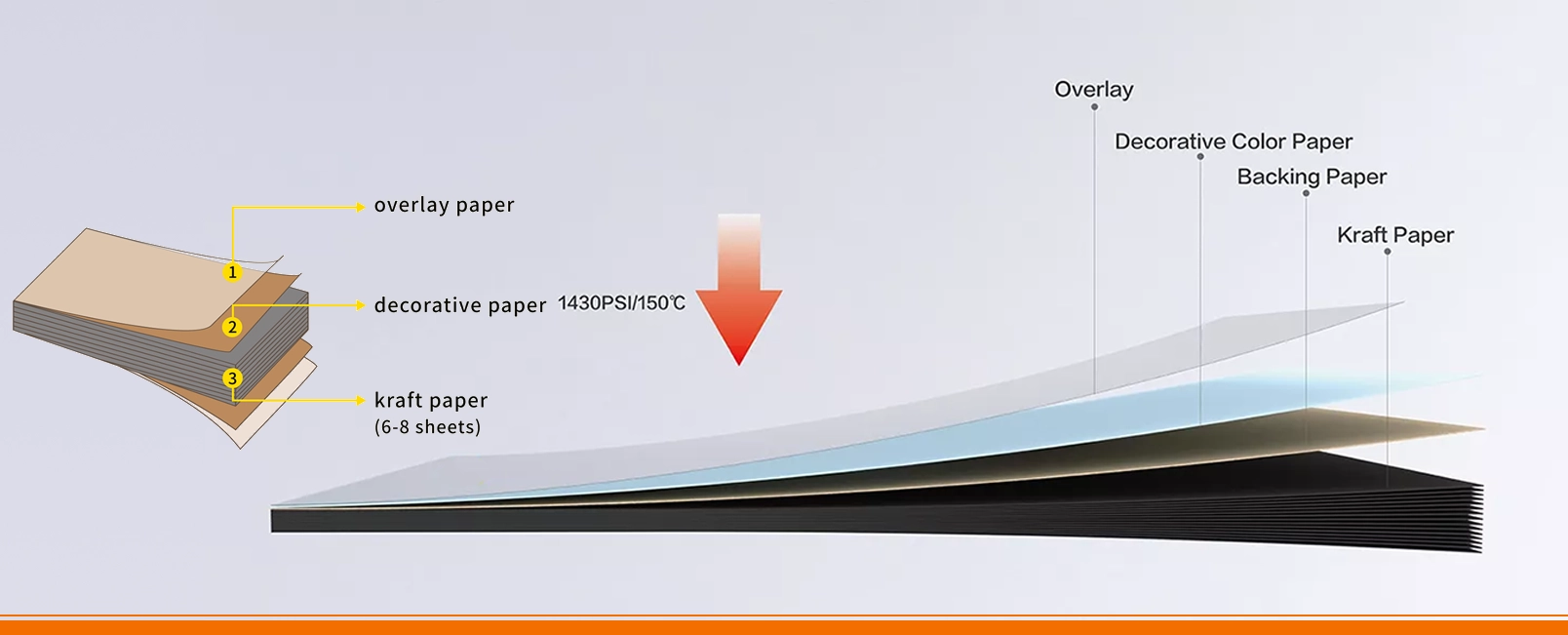

HPL is a multi-layered material engineered for maximum durability.

It consists of 6–8 layers of kraft paper impregnated with phenolic resin, topped with a decorative paper and a clear overlay impregnated with melamine resin.

- Bonding: Fused under high heat (100–140°C) and intense pressure (1000+ psi).

- Form: Produced as a thin sheet (0.7–1.5mm) which must be bonded to a substrate (MDF, Plywood, Particleboard) using adhesive and high pressure.

- Post-forming: Specific grades can be heated to curve around edges (post-forming).

Performance & Durability

- Superior Resistance: Extremely resistant to impact, scratches, abrasion, and heat.

- Water/Moisture: High resistance to moisture and humidity (does not warp easily when properly bonded).

- Hygiene: Non-porous surface, easy to clean, suitable for healthcare and food service.

Performance & Durability

High-pressure laminate is regarded as one of the most durable decorative surface materials. It performs exceptionally well in both horizontal and vertical applications, finding widespread use in furniture, shop countertops, display cabinet shelves (high-frequency contact), public area wall/column cladding, and decorative panels for outdoor or high-humidity zones.

High-pressure laminate (HPL) is exceptionally hard-wearing, making it ideal for high-traffic domestic areas and surfaces in retail, office, and hospitality settings. It is also frequently employed for vertical and horizontal surfaces in hospitals and clinics.

The properties of HPL also enable post-forming. This technique has evolved considerably and now encompasses various advanced edge-finishing processes, such as S-curves and multiple radii, capable of replicating the appearance of more costly stone installations.

Low-Pressure Laminate

Alternative Names: Melamine, Melamine Board, TFL (Thermally Fused Laminate)

Process Overview

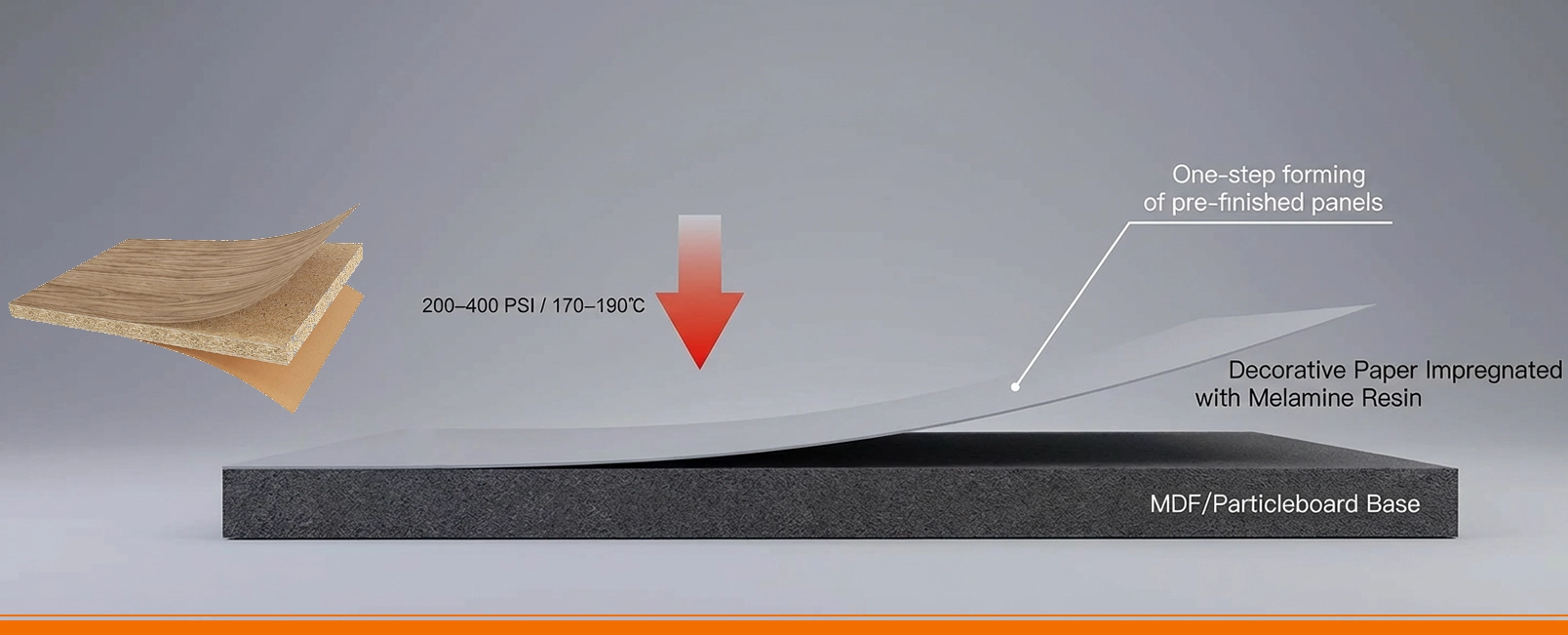

LPL is a cost-effective, “one-step” surfacing solution. It consists of a single layer (or double) of decorative paper impregnated with melamine resin.

Bonding: The paper is thermally fused directly onto the substrate (Particleboard or MDF) at 170–190°C and lower pressure (200–400 psi).

Form: Comes as a pre-finished board ready to cut; no secondary gluing/lamination is required.

Structure: No kraft paper core; the surface layer is very thin (0.1–0.5mm).

Performance & Durability

Moderate Resistance: Good resistance to stains and light scratches, but lower impact resistance compared to HPL.

Limitations: Prone to chipping at edges if not cut precisely; susceptible to water damage if edges are not sealed (substrate swelling).

Cost-Efficiency: Significantly lower production cost.

Performance & Durability

Shop cabinet carcasses, door panels, back panels, low-contact shelves, decorative wall panels, office furniture, non-load-bearing side panels of display cabinets.

It is also suitable for healthcare, hospitality, commercial and retail premises. Decorative edge finishing is often required, with options for edged or unedged, as well as single-sided or double-sided treatment.

| Features | High-Pressure Laminate (HPL) | Low-Pressure Laminate (LPL) |

|---|---|---|

| Alternative Name | Laminate | Melamine |

| Durability | More durable, scratch-resistant, impact-resistant | More affordable, but with weaker wear resistance |

| Process Overview | Multiple layers of kraft paper impregnated with resin, pressed at high temperature and pressure | Single layer of decorative paper impregnated with melamine resin, pressed at low pressure |

| Structural Features | Multi-layer reinforcement structure | No multi-layer reinforcement, only a thin decorative layer |

| Cost | Higher (material cost + secondary processing fee) | Lower (one-step forming, no extra lamination required) |

| Machinability | Requires professional equipment for cutting and edge banding | Easy to cut and directly edge-banded for assembly |

| Recommended Applications | Shop cashier countertops High-contact display shelves | Shop cabinet carcasses Door panels Back panels |

About This Comparison

- HPL is recommended for high-traffic and high-wear areas due to its superior durability

- LPL is more cost-effective for interior components with less wear exposure

- The choice between HPL and LPL depends on usage scenario, budget, and durability requirements

Discover the perfect decorative surface

Contact us for the most comprehensive product information on decorative surface solutions, helping you find the ideal match for your unique requirements.

Discover the perfect decorative surface

Contact us for the most comprehensive product information on decorative surface solutions, helping you find the ideal match for your unique requirements.